Gear stl

Author: a | 2025-04-24

Metal Gear Rex Figure Articulated, Metal Gear Stl 3D Printing, Metal Gear Stl 3D design, Metal Gear Digital STL, Metal Gear Figure Model (239) $ 3.98. Digital Download Add to Favorites Gray Fox Full Cosplay Exoskeleton STLS (No Helmet) (40) $ 25.00. Digital Download

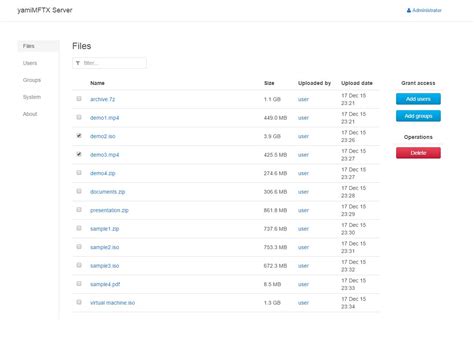

slide Gear STL by MK_Design

The Air Engine.Slide "Rod Piston.stl" into "Head Cylinder.stl" noting the orientation of the hole in "Rod Piston.stl".Press "Piston.stl" onto "Rod Piston.stl" positioning "Piston.stl" exactly 28mm from the end of "Rod Piston.stl". This is the cylinder head assembly.Slide "Valve.stl" into "Cylinder Center Top Port.stl" noting the orientation of the valve holes. This is the cylinder assembly.Press the cylinder head assembly onto the cylinder assembly. This is the air engine assembly.At this point, you should be able to easily and smoothly move the valve and piston rod in and out of the cylinder. If not, disassemble the air engine assembly and lightly file until they do.Step 3: Assemble and Test the Crankshaft.Slide "Journal Crankshaft 10mm 2.stl" into the hole in "Arm Piston.stl" noting the orientation of "Arm Piston.stl".Press "Journal Crankshaft 10mm 1.stl" onto the octagonal pin on "Journal Crankshaft 10mm 2.stl" noting the orientation of each.Slide "Journal Crankshaft 4mm 2.stl" into the hole in "Arm Valve.stl" noting the orientation of "Arm Valve.stl".Press "Journal Crankshaft 4mm 1.stl" onto the octagonal pin on "Journal Crankshaft 4mm 2.stl" noting the orientation of each.Slide "Journal Crankshaft 4mm 1.stl" into the hole in "Chassis Center.stl".Press "Journal Crankshaft 10mm 2.stl" onto the octagonal pin on "Journal Crankshaft 4mm1.stl" noting the orientation of the two journals. This is the crankshaft assembly.Press the air engine assembly into "Chassis Right.stl".Press the crankshaft assembly into "Chassis Right.stl", noting the orientation of each.Press "Chassis Left.stl" onto the air engine and crankshaft assemblies.Slide "Bushing Journal Crankshaft 10mm 1.stl" into the crankshaft hole in "Chassis Right.stl" then press into "Journal Crankshaft 10mm 1.stl".Slide "Gear Journal Crankshaft 4mm 2.stl" into the crankshaft hole in "Chassis Left.stl" then press into "Journal Crankshaft 4mm 2.stl". This is the chassis assembly. At this time, the crankshaft should rotate freely with no drag or catching. If it does drag or catch, carefully examine the entire crankshaft making sure it is "true" (meaning all journal surfaces are parallel to each other and the chassis surfaces, and no journal, bushing or gear rotates out of true).Step 4: Connect the Air Engine to the Crankshaft, Then Add the Rear Wheels.Using "Pin Arm Piston.stl", attach "Arm Piston.stl" to "Rod Piston.stl". Once attached, rotate the crankshaft to ensure no drag or catching occurs. If it does drag or catch, the air engine piston chain (includes the parts "Rod Piston.stl", "Head Cylinder.stl", "Piston.stl" and "Cylinder.stl") needs to be carefully filed until no drag or catch occurs.Using "Pin Arm Valve.stl", attach "Arm Valve.stl" to "Valve.stl". Once attached, rotate the crankshaft to ensure no drag or catching occurs. If it does drag or catch, the air engine valve chain (includes the parts "Valve.stl", "Head Cylinder.stl" and "Cylinder.stl") needs to be carefully filed until no drag or catch occurs.Place o-rings onto "Wheel Left Rear.stl" and "Wheel Right Rear.stl", then slide "Wheel Left Rear.stl" into the rear axle holes in the chassis assembly from the left (gear) side of the chassis assembly.Press "Wheel Right Rear.stl" onto the octagonal pin on "Wheel Left Rear.stl". The wheels should rotate freely with no Cylinder and positioning and resizing it where needed.Once the desired look is achieved, export your model. Export or slice and export as G-code to print.The changes will appear after export.5. Preparing the Model for PrintingCheck for Errors: Use the “Fix by Windows repair algorithm” by selecting the gear on the right of the model in the selection pain.Add Supports: Automatically generate supports if needed.Slice the Model: Click “Slice Now”to prepare the model for printing.6. Exporting the Edited STL FileExport G-Code: Once the model is sliced, click “Export G-Code”to save the file for printing.Export STL: If you need to save the edited STL file, click File > Export > Export as STL.Common Issues and SolutionsHow to Fix Non-Manifold Edges?Non-manifold edges can cause print issues. Right click on the model and use “Fix by Windows repair algorithm” l to identify and fix these problems automatically.How to Reduce Polygon Count?To reduce the polygon count in the model, right-click on the gear and select “Simplify Model.” You can also click on the model in the main window, right-click on the model, and the option will appear there as well.How to Merge Multiple STL Files?Import Additional Files: Click Addto import multiple STL files.Combine Models: Position the models as needed, then export them as a single STL file.FAQsWhat is the Easiest Way to Edit STL Files in PrusaSlicer?Using the basic tools like move, scale, and rotate in PrusaSlicer’s intuitive interface makes it accessible for beginners.Can PrusaSlicer Handle Complex STL Files?While PrusaSlicer is best suited for basic edits and print preparation, it can handle moderately complex models effectively.How Do I Repair a Corrupted STL File in PrusaSlicer?Use the “Fix by Windows repair algorithm” tool to automatically identify and repair corruptions in STL files.ConclusionEditing STL files in PrusaSlicer provides a simple and effective approach to customizing 3D models. By following this comprehensive guide and practicing with examples like the 3D rabbit, you can make precise modifications and ensure high-quality prints. PrusaSlicer’s user-friendly interface and essential editing tools make it an ideal choice for both beginners and experienced users.Gear Free 3D Models Stl - .stl download - Free3D

STLBase is a Search Engine for 3D printable Models and STL Files. Click on images to download ultimaker extruder gear STL files for your 3D Printer. 123» Order Printed Ultimaker springy wheel DOWNLOAD Cults. Order Printed 2.85mm Filament Geared Bowden Extruder Feeder DOWNLOAD Thingiverse Order Printed Ultimaker - Ultistruder Mk2 DOWNLOAD Cults. Order Printed One comment DOWNLOAD Cults. Order Printed Ultimaker Nozzle Mk2 for 3mm filament DOWNLOAD Cults. Order Printed TORANADO + ULTIMAKER + Gear Extruder (NEMA17 + NEMA14) DOWNLOAD Thingiverse Order Printed Dual geared extruder support with fan, for ultimaker DOWNLOAD Thingiverse Order Printed Ultimaker 2 Extruder Gear Housing + 1.75mm & 3.00mm Conversion DOWNLOAD Thingiverse Order Printed Ultimaker original UMO(+) feeder big gear wheel handle DOWNLOAD Thingiverse Order Printed extruder with gear for Ultimaker DOWNLOAD Thingiverse Order Printed B2D Extruder - Strong and Silent Bowden Extruder DOWNLOAD Thingiverse Order Printed Compact Bowden Extruder adjusted for Tatsu drive gear and ultimaker frame DOWNLOAD Thingiverse Order Printed Extruder drive gear for Ultimaker 2+ extended DOWNLOAD Thingiverse Order Printed J-Max_Bowden Belt Extruder (feeder) V1.0 DOWNLOAD Thingiverse up to 50% Off Ad $16.29 Shop Now! TriangleLab E3D V6 Hotend Order Printed Souvenir Pendant for Maker Faire - UMO extruder DOWNLOAD Thingiverse Order Printed Ulticampy Geared Support (Based on Alex extruder) DOWNLOAD Thingiverse Order Printed HerringBone Gear for H3 Extruder adaption for Ultimaker DOWNLOAD Pinshape Order Printed Ultifeeder the ultimate extruder feeder for your Ultimaker 2 DOWNLOAD Thingiverse Order Printed ultimaker original mod: astrosyn extruder gear DOWNLOAD Thingiverse Order Printed USB Cap DOWNLOAD Thingiverse Order Printed Ultimaker extruder gears DOWNLOAD Thingiverse Order Printed Ultimaker extruder gear upgrade, retraction friendly DOWNLOAD Thingiverse Order Printed HerringBone Gear for H3 Extruder adaption for Ultimaker DOWNLOAD Thingiverse 123» Related ultimaker extruder gear STL files ultimaker z end stop ultimaker new ultimaker drink ultimaker noise reduction ultimaker character ultimaker creality ender 2 ultimaker scale ultimaker bed ultimaker make a bot ultimaker tape ultimaker stock ultimaker colou ultimaker printer accessories ultimaker geometri ultimaker axis tool ultimaker quick ultimaker cool ultimaker 4s ultimaker desk toy ultimaker gopro 3 ultimaker gopro hero 3 ultimaker chain ultimaker math ultimaker camera mount ultimaker amplifier ultimaker replacement ultimaker printer part ultimaker mavic ultimaker pcb ultimaker racer ultimaker rna ultimaker stem ultimaker conversion ultimaker wanhao i3 ultimaker smart ultimaker upgrade ultimaker 3d design ultimaker toy boat. Metal Gear Rex Figure Articulated, Metal Gear Stl 3D Printing, Metal Gear Stl 3D design, Metal Gear Digital STL, Metal Gear Figure Model (239) $ 3.98. Digital Download Add to Favorites Gray Fox Full Cosplay Exoskeleton STLS (No Helmet) (40) $ 25.00. Digital DownloadSTL Tonehub Update - The Gear Forum

4377584 3d models found related to 3d printed gears of war. gears of war symbol 3D print model cgtraderIntricate Machine Emblazoned as Gear of Warfare Significance Measurement Values Exposed Dimension Specifications Reveal a Three-Component System X Dimension Equals 279 Millimeters, Defining Vertical Aspect Y Dimension Quantifies 41 Millimeters,... Gears of War Spinner 3D print model cgtrader... prize to claim. We strive to level up, not just in video games, but in life itself, constantly seeking self-improvement and progression. And when we finally reach that long-awaited achievement, we celebrate with the triumphant shout of "Yes!" JD Fenix Gears of War 4 Armor 3D print model cgtrader This wearable suit system includes: Front side gear Backside gear Suit Design Details The JD Fenix Gears of War armor pieces can be easily scaled up or down in any 3D software like Netfabb or similar to ensure proper fit and printing accuracy on the... Lancer - Gears of War - Printable 3d model - STL 3D print model cgtraderWe glad introduce you 3d model - STL files - to print your own Lancer from world well know game Gears of War 5. Lot include: 114 stl files to 3d printing (biggest part demensions: 153*140*65 mm, longest part: 171mm). 5 stl files - stand for Lancer.... Complete Character Set Gears of War 3D Model STL File 3D Print cults3dThis is all (44) of the Gears of War Character models I have listed in one package, at half the price of buying them all individually! Please see individual listings for details on each file.These are fan models, and by far the best to be found... Complete Enemy Set Gears of War 3D Model STL File 3D Print cults3dThis is all (50) of the Gears of War Enemy models I have listed in one package, at half the price of buying them all individually! Please see individual listings for details on each file.These are fan models, and by far the best to be found... Gears of War 4 Gnasher keychan thingiverseThsi a complete version for a keychan of this model: Original version: gears of war 4 gnasher Introduction: Balloon Powered Single Cylinder Air Engine Toy TrainBalloon Powered Single Cylinder Air Engine Toy Train is a balloon powered toy train engine based on my earlier air engine design ( and single cylinder air engine rolling chassis design ( In order to move the increased weight of this design, I added a 4 to 1 (driven to drive) gear reduction. Even with the gear reduction, this vehicle when well tuned can run over 40 feet on a smooth surface, albeit at a much slower speed.My wife laughed yet again so hard when this toy train engine chugged through the kitchen and into the family room that, well, now there's now quite a few more of them (this time she liked the colors I chose). And yes, it still sounds like a steam engine. I even clamped my iPhone to "Top.stl" and gave it a ride, I've included the video.You will need to purchase 4 "AS568" #219 o-rings (1 5/16" I.D., 1 9/16" O.D, 1/8" section) for the tires and at least 1 "punch balloon" (I found mine at a local party supply store, but they also are available on line). I probably forgot a file or two or something, so if you have any questions, please feel free to ask. Designed using Autodesk Fusion 360, sliced using Cura 2.3.1, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker 3 Extended.Step 1: Print, Purchase and Prepare the Parts.As mentioned in the introduction, you will need to purchase 4 "AS568" #219 o-rings (1 5/16" I.D., 1 9/16" O.D, 1/8" section) for the tires and at least 1 "punch balloon" (I found mine at a local party supply store, but they also are available on line) for the "fuel tank".I printed my parts on an Ultimaker 2+ Extended and an Ultimaker 3 Extended using .1mm vertical resolution and 100% infill for "Cylinder.stl", "Rod Balloon.stl", "Rod Balloon Coupler", "Rod Balloon Hook", "Journal Crankshaft 4mm 1.stl", "Journal Crankshaft 4mm 2.stl", "Journal Crankshaft 10mm 1.stl", "Journal Crankshaft 10mm 2.stl", "Gear Journal Crankshaft 4mm 2.stl" and "Bushing Journal Crankshaft 10mm 1.stl", 20% infill for the remaining parts, and no supports.This is a precision print and build and as such requires a clean and level build plate (to eliminate warping) and trimming, filing and/or sanding (to remove edge oozing). Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on the colors you chose and your printer settings, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely sure that all build plate "ooze" is removed and that all edges are smooth. I used a flat jewelers file and plenty of patience to perform this step.Study "Assembly.stl", the cad output of Autodesk Fusion 360 and the photographs carefully noting the locations and positions of the various components as assembly proceeds.Step 2: Assemble and TestGear Sphere Stl File - Etsy

Sidebar to slice the model into parts.Example: Cut the 3D rabbit in half to print in two parts. In this mode it is also possible to create dovetails to make parts friction fit together after 3D printing. Supports: Add or remove supports manually using the “Paint on Supports”Example: Adding custom supports to the rabbit's ears. Doing this helps to avoid printing failures using support material.Modifier Meshes: Apply modifier meshes to specific areas for detailed modifications.Example: In this example, I added a sphere to make the rabbit's tail more round, then exported it as an STL file. The exported file can be sliced in PrusaSlicer or imported into CURA.Right-click on the object and right-click on the model name. Select “Add part” and then either select an “object” or “load” your own model to add an additional model to the selected model.Adding Text or Logos: Use the “Add Part”feature to incorporate text or logos into yourExample: in this example we are adding text to a STL file useful for adding in inbuilt labels on 3D prints.Right click on the model name, right click “add text” or SVG and input your text. Select option “Use Surface” drag text to locationMerging Models: Import multiple STL files and merge them into a single model.Example: in this example we are combining two 3D models as one.Right click on the model name from the file name on the right and add a platform resize and reposition if needed. You can load a different separate model as well. Reposition the base underneath the rabbit. If you want to change the parameters of the object additional options are located in the gear icon if you right click on it.Boolean Operations: Perform basic boolean operations (e.g., union, subtraction) to modify complex shapes.Example: Subtract a cylinder from the rabbit to create a hole.Select the model. If it has a complex mesh, go to the gear on the left, right-click, and select “Simplify.” If this isn't done, Boolean operations will not occur correctly and an error message will appear.Then, right-click and add a “Negative Volume.” In this case, we are adding aGear Ball. STL File - Etsy

Dd Ap001 Bridge V01.Stl Dd Ap001 Chunk A V01.Stl Dd Ap001 Chunk B V01.Stl Dd Ap001 Chunk C V01.Stl Dd Ap001 Chunk Complete.stl Dd Ap001 Chunk D V01.Stl Dd Ap001 Chunk E V01.Stl Dd Ap001 Chunk F V01.Stl Dd Ap001 Dun Floor B Wood Plank Fcw01 V01.Stl Dd Ap001 Dun Floor B Wood Plank Fcw02 V01.Stl Dd Ap001 Dun Floor B Wood Plank Fcw03 V01.Stl Dd Ap001 Dun Floor B Wood Plank Fw01 V01.Stl Dd Ap001 Dun Floor B Wood Plank Fw02 V01.Stl Dd Ap001 Dun Floor B Wood Plank Sc02 V01.Stl Dd Ap001 Dun Floor Flagstone Random Small F01 V01.Stl Dd Ap001 Dun Floor Flagstone Random Small F02 V01.Stl Dd Ap001 Dun Stairs V01.Stl Dd Ap001 Gate Doors V01.Stl Dd Ap001 Gate Frame Base V01.Stl Dd Ap001 Gate Frame Middle V02.Stl Dd Ap001 Gate Frame Top V01.Stl Dd Ap001 Gate Gears V01.Stl Dd Ap001 Gate Key V01.Stl Dd Ap001 T Oll Cave V01.Stl Dd Ap001 Toll Bridge Sign V01.Stl Dd Ap001 Wld Floor Grass F01 V01.Stl Dd Ap001 Wld Floor Grass F02 V01.Stl Dd Ap001 Wld Floor Jetty F01 V02.Stl Dd Ap001 Wld Floor Jetty F02 V02.Stl Dd Ap001 Wld Floor Jetty F03 V02.Stl Dd Ap001 Wld Floor Path F01 V01.Stl Dd Ap001 Wld Floor Path F02 V01.Stl Dd Ap001 Wld Floor Water F01 V01.Stl Dd Ap001 Wld Floor Water Rocks Cnr F01 V01.Stl Dd Ap001 Wld Floor Water Rocks F01 V01.Stl Dd Ap001 Wld Floor Water Rocks F02 V01.Stl Dd Grid 2X3 V01.Stl Dd Grid 3X3 V01.Stl Dd Grid 3X4 V01.Stl Dd Level 1X1 V01.Stl Dd Level 1X3 V01.Stl Dd Level 2X3 V01.Stl Dd Level 3X3 V01.Stl Dd Plug X V01.Stl Dun Edge Bricks High 1X A V01.Stl Dun Edge Bricks High 1X B V01.Stl Dun Edge Bricks High 1X Long V01.Stl Dun Edge Bricks High 2X V01.Stl Dun Edge Bricks High 3X V01.Stl (Repaired) Dun Edge Stairs High 1X V01.Stl Dun Greeble Chain V01.Stl Dun Greeble Stone 01 V01.Stl Dun Greeble Stone 03 V01.Stl Dun Single Door Bars Upright V01.Stl Dun Single Door Frame Cnr A V02.Stl Scatter Barrel Closed V01.Stl Scatter Barrel Open V01.Stl Scatter Crates And Barrels 01 V01.Stl Wld Edge Rocks High 1X Long V01.Stl Wld Edge Rocks High 1X V01.Stl Wld Edge Rocks High 2X V01.Stl Wld Edge Water High 1X A V01.Stl Wld Edge Water High 1X B V01.Stl Wld Edge Water Rocks High 1X A V01.Stl Wld Edge Water Rocks High 1X B V01.Stl. Metal Gear Rex Figure Articulated, Metal Gear Stl 3D Printing, Metal Gear Stl 3D design, Metal Gear Digital STL, Metal Gear Figure Model (239) $ 3.98. Digital Download Add to Favorites Gray Fox Full Cosplay Exoskeleton STLS (No Helmet) (40) $ 25.00. Digital DownloadMetal Gear Solid Stl - Etsy

.obj .stl .unknown .max$89 14,933 .obj .stl .wrl .ztl$19 6,905 .stl .obj .max .fbx .3ds$39 7,275 .stl .obj .fbx .max$19 3,095 .stl .obj .fbx .dae .3ds .blend$4 3,324 .obj .stl .wrl .ztl$19 2,918 .blend .obj .stl$24 3,646 .max .blend .fbx .3ds .obj .stl$29 714 .blend .fbx .obj .stl$25 531 .stl .3ds .obj .max$49 4,778 .3ds .c4d .fbx .obj .stl .unknown$25 733 .3ds .c4d .fbx .obj .stl .unknown$30 559 .max .obj .3ds .fbx .stl$24 236 .blend .fbx .obj .stl$60 308 .max .blend .fbx .dae .3ds .obj .stl$29 192 .obj .fbx .max .stl$8 127 .blend .obj .stl$24 4,641 .wrl .fbx .obj .stl .dae .blend .ma$40 3,338 .3ds .fbx .blend .obj .stl$20 170 .blend .fbx .ma .obj .stl .unknown$30 2 .obj .max .stl .fbx .3ds$29 384 .obj .fbx .max .stl$3 137 .ztl .stl .obj .max .fbx .3ds$29 2,279 .max .obj .stl .ztl .3ds$23 183 .blend .3ds .dae .stl .obj .lwo$10 10 .obj .fbx .max .stl$3 161 .ige .stl .sldpr .x .dae .fbx .blend$9 43 .obj .fbx .max .stl$5 273 .fbx .max .obj .stl$15 14 .fbx .max .obj .stl$15 18 .ztl .obj .fbx .max .3ds .stl$99 4 .blend .c4d .fbx .max .obj .stl$5 8Comments

The Air Engine.Slide "Rod Piston.stl" into "Head Cylinder.stl" noting the orientation of the hole in "Rod Piston.stl".Press "Piston.stl" onto "Rod Piston.stl" positioning "Piston.stl" exactly 28mm from the end of "Rod Piston.stl". This is the cylinder head assembly.Slide "Valve.stl" into "Cylinder Center Top Port.stl" noting the orientation of the valve holes. This is the cylinder assembly.Press the cylinder head assembly onto the cylinder assembly. This is the air engine assembly.At this point, you should be able to easily and smoothly move the valve and piston rod in and out of the cylinder. If not, disassemble the air engine assembly and lightly file until they do.Step 3: Assemble and Test the Crankshaft.Slide "Journal Crankshaft 10mm 2.stl" into the hole in "Arm Piston.stl" noting the orientation of "Arm Piston.stl".Press "Journal Crankshaft 10mm 1.stl" onto the octagonal pin on "Journal Crankshaft 10mm 2.stl" noting the orientation of each.Slide "Journal Crankshaft 4mm 2.stl" into the hole in "Arm Valve.stl" noting the orientation of "Arm Valve.stl".Press "Journal Crankshaft 4mm 1.stl" onto the octagonal pin on "Journal Crankshaft 4mm 2.stl" noting the orientation of each.Slide "Journal Crankshaft 4mm 1.stl" into the hole in "Chassis Center.stl".Press "Journal Crankshaft 10mm 2.stl" onto the octagonal pin on "Journal Crankshaft 4mm1.stl" noting the orientation of the two journals. This is the crankshaft assembly.Press the air engine assembly into "Chassis Right.stl".Press the crankshaft assembly into "Chassis Right.stl", noting the orientation of each.Press "Chassis Left.stl" onto the air engine and crankshaft assemblies.Slide "Bushing Journal Crankshaft 10mm 1.stl" into the crankshaft hole in "Chassis Right.stl" then press into "Journal Crankshaft 10mm 1.stl".Slide "Gear Journal Crankshaft 4mm 2.stl" into the crankshaft hole in "Chassis Left.stl" then press into "Journal Crankshaft 4mm 2.stl". This is the chassis assembly. At this time, the crankshaft should rotate freely with no drag or catching. If it does drag or catch, carefully examine the entire crankshaft making sure it is "true" (meaning all journal surfaces are parallel to each other and the chassis surfaces, and no journal, bushing or gear rotates out of true).Step 4: Connect the Air Engine to the Crankshaft, Then Add the Rear Wheels.Using "Pin Arm Piston.stl", attach "Arm Piston.stl" to "Rod Piston.stl". Once attached, rotate the crankshaft to ensure no drag or catching occurs. If it does drag or catch, the air engine piston chain (includes the parts "Rod Piston.stl", "Head Cylinder.stl", "Piston.stl" and "Cylinder.stl") needs to be carefully filed until no drag or catch occurs.Using "Pin Arm Valve.stl", attach "Arm Valve.stl" to "Valve.stl". Once attached, rotate the crankshaft to ensure no drag or catching occurs. If it does drag or catch, the air engine valve chain (includes the parts "Valve.stl", "Head Cylinder.stl" and "Cylinder.stl") needs to be carefully filed until no drag or catch occurs.Place o-rings onto "Wheel Left Rear.stl" and "Wheel Right Rear.stl", then slide "Wheel Left Rear.stl" into the rear axle holes in the chassis assembly from the left (gear) side of the chassis assembly.Press "Wheel Right Rear.stl" onto the octagonal pin on "Wheel Left Rear.stl". The wheels should rotate freely with no

2025-04-18Cylinder and positioning and resizing it where needed.Once the desired look is achieved, export your model. Export or slice and export as G-code to print.The changes will appear after export.5. Preparing the Model for PrintingCheck for Errors: Use the “Fix by Windows repair algorithm” by selecting the gear on the right of the model in the selection pain.Add Supports: Automatically generate supports if needed.Slice the Model: Click “Slice Now”to prepare the model for printing.6. Exporting the Edited STL FileExport G-Code: Once the model is sliced, click “Export G-Code”to save the file for printing.Export STL: If you need to save the edited STL file, click File > Export > Export as STL.Common Issues and SolutionsHow to Fix Non-Manifold Edges?Non-manifold edges can cause print issues. Right click on the model and use “Fix by Windows repair algorithm” l to identify and fix these problems automatically.How to Reduce Polygon Count?To reduce the polygon count in the model, right-click on the gear and select “Simplify Model.” You can also click on the model in the main window, right-click on the model, and the option will appear there as well.How to Merge Multiple STL Files?Import Additional Files: Click Addto import multiple STL files.Combine Models: Position the models as needed, then export them as a single STL file.FAQsWhat is the Easiest Way to Edit STL Files in PrusaSlicer?Using the basic tools like move, scale, and rotate in PrusaSlicer’s intuitive interface makes it accessible for beginners.Can PrusaSlicer Handle Complex STL Files?While PrusaSlicer is best suited for basic edits and print preparation, it can handle moderately complex models effectively.How Do I Repair a Corrupted STL File in PrusaSlicer?Use the “Fix by Windows repair algorithm” tool to automatically identify and repair corruptions in STL files.ConclusionEditing STL files in PrusaSlicer provides a simple and effective approach to customizing 3D models. By following this comprehensive guide and practicing with examples like the 3D rabbit, you can make precise modifications and ensure high-quality prints. PrusaSlicer’s user-friendly interface and essential editing tools make it an ideal choice for both beginners and experienced users.

2025-04-20STLBase is a Search Engine for 3D printable Models and STL Files. Click on images to download ultimaker extruder gear STL files for your 3D Printer. 123» Order Printed Ultimaker springy wheel DOWNLOAD Cults. Order Printed 2.85mm Filament Geared Bowden Extruder Feeder DOWNLOAD Thingiverse Order Printed Ultimaker - Ultistruder Mk2 DOWNLOAD Cults. Order Printed One comment DOWNLOAD Cults. Order Printed Ultimaker Nozzle Mk2 for 3mm filament DOWNLOAD Cults. Order Printed TORANADO + ULTIMAKER + Gear Extruder (NEMA17 + NEMA14) DOWNLOAD Thingiverse Order Printed Dual geared extruder support with fan, for ultimaker DOWNLOAD Thingiverse Order Printed Ultimaker 2 Extruder Gear Housing + 1.75mm & 3.00mm Conversion DOWNLOAD Thingiverse Order Printed Ultimaker original UMO(+) feeder big gear wheel handle DOWNLOAD Thingiverse Order Printed extruder with gear for Ultimaker DOWNLOAD Thingiverse Order Printed B2D Extruder - Strong and Silent Bowden Extruder DOWNLOAD Thingiverse Order Printed Compact Bowden Extruder adjusted for Tatsu drive gear and ultimaker frame DOWNLOAD Thingiverse Order Printed Extruder drive gear for Ultimaker 2+ extended DOWNLOAD Thingiverse Order Printed J-Max_Bowden Belt Extruder (feeder) V1.0 DOWNLOAD Thingiverse up to 50% Off Ad $16.29 Shop Now! TriangleLab E3D V6 Hotend Order Printed Souvenir Pendant for Maker Faire - UMO extruder DOWNLOAD Thingiverse Order Printed Ulticampy Geared Support (Based on Alex extruder) DOWNLOAD Thingiverse Order Printed HerringBone Gear for H3 Extruder adaption for Ultimaker DOWNLOAD Pinshape Order Printed Ultifeeder the ultimate extruder feeder for your Ultimaker 2 DOWNLOAD Thingiverse Order Printed ultimaker original mod: astrosyn extruder gear DOWNLOAD Thingiverse Order Printed USB Cap DOWNLOAD Thingiverse Order Printed Ultimaker extruder gears DOWNLOAD Thingiverse Order Printed Ultimaker extruder gear upgrade, retraction friendly DOWNLOAD Thingiverse Order Printed HerringBone Gear for H3 Extruder adaption for Ultimaker DOWNLOAD Thingiverse 123» Related ultimaker extruder gear STL files ultimaker z end stop ultimaker new ultimaker drink ultimaker noise reduction ultimaker character ultimaker creality ender 2 ultimaker scale ultimaker bed ultimaker make a bot ultimaker tape ultimaker stock ultimaker colou ultimaker printer accessories ultimaker geometri ultimaker axis tool ultimaker quick ultimaker cool ultimaker 4s ultimaker desk toy ultimaker gopro 3 ultimaker gopro hero 3 ultimaker chain ultimaker math ultimaker camera mount ultimaker amplifier ultimaker replacement ultimaker printer part ultimaker mavic ultimaker pcb ultimaker racer ultimaker rna ultimaker stem ultimaker conversion ultimaker wanhao i3 ultimaker smart ultimaker upgrade ultimaker 3d design ultimaker toy boat

2025-04-024377584 3d models found related to 3d printed gears of war. gears of war symbol 3D print model cgtraderIntricate Machine Emblazoned as Gear of Warfare Significance Measurement Values Exposed Dimension Specifications Reveal a Three-Component System X Dimension Equals 279 Millimeters, Defining Vertical Aspect Y Dimension Quantifies 41 Millimeters,... Gears of War Spinner 3D print model cgtrader... prize to claim. We strive to level up, not just in video games, but in life itself, constantly seeking self-improvement and progression. And when we finally reach that long-awaited achievement, we celebrate with the triumphant shout of "Yes!" JD Fenix Gears of War 4 Armor 3D print model cgtrader This wearable suit system includes: Front side gear Backside gear Suit Design Details The JD Fenix Gears of War armor pieces can be easily scaled up or down in any 3D software like Netfabb or similar to ensure proper fit and printing accuracy on the... Lancer - Gears of War - Printable 3d model - STL 3D print model cgtraderWe glad introduce you 3d model - STL files - to print your own Lancer from world well know game Gears of War 5. Lot include: 114 stl files to 3d printing (biggest part demensions: 153*140*65 mm, longest part: 171mm). 5 stl files - stand for Lancer.... Complete Character Set Gears of War 3D Model STL File 3D Print cults3dThis is all (44) of the Gears of War Character models I have listed in one package, at half the price of buying them all individually! Please see individual listings for details on each file.These are fan models, and by far the best to be found... Complete Enemy Set Gears of War 3D Model STL File 3D Print cults3dThis is all (50) of the Gears of War Enemy models I have listed in one package, at half the price of buying them all individually! Please see individual listings for details on each file.These are fan models, and by far the best to be found... Gears of War 4 Gnasher keychan thingiverseThsi a complete version for a keychan of this model: Original version: gears of war 4 gnasher

2025-04-14Introduction: Balloon Powered Single Cylinder Air Engine Toy TrainBalloon Powered Single Cylinder Air Engine Toy Train is a balloon powered toy train engine based on my earlier air engine design ( and single cylinder air engine rolling chassis design ( In order to move the increased weight of this design, I added a 4 to 1 (driven to drive) gear reduction. Even with the gear reduction, this vehicle when well tuned can run over 40 feet on a smooth surface, albeit at a much slower speed.My wife laughed yet again so hard when this toy train engine chugged through the kitchen and into the family room that, well, now there's now quite a few more of them (this time she liked the colors I chose). And yes, it still sounds like a steam engine. I even clamped my iPhone to "Top.stl" and gave it a ride, I've included the video.You will need to purchase 4 "AS568" #219 o-rings (1 5/16" I.D., 1 9/16" O.D, 1/8" section) for the tires and at least 1 "punch balloon" (I found mine at a local party supply store, but they also are available on line). I probably forgot a file or two or something, so if you have any questions, please feel free to ask. Designed using Autodesk Fusion 360, sliced using Cura 2.3.1, and printed in PLA on an Ultimaker 2+ Extended and an Ultimaker 3 Extended.Step 1: Print, Purchase and Prepare the Parts.As mentioned in the introduction, you will need to purchase 4 "AS568" #219 o-rings (1 5/16" I.D., 1 9/16" O.D, 1/8" section) for the tires and at least 1 "punch balloon" (I found mine at a local party supply store, but they also are available on line) for the "fuel tank".I printed my parts on an Ultimaker 2+ Extended and an Ultimaker 3 Extended using .1mm vertical resolution and 100% infill for "Cylinder.stl", "Rod Balloon.stl", "Rod Balloon Coupler", "Rod Balloon Hook", "Journal Crankshaft 4mm 1.stl", "Journal Crankshaft 4mm 2.stl", "Journal Crankshaft 10mm 1.stl", "Journal Crankshaft 10mm 2.stl", "Gear Journal Crankshaft 4mm 2.stl" and "Bushing Journal Crankshaft 10mm 1.stl", 20% infill for the remaining parts, and no supports.This is a precision print and build and as such requires a clean and level build plate (to eliminate warping) and trimming, filing and/or sanding (to remove edge oozing). Prior to assembly, test fit and trim, file, sand, etc. all parts as necessary for smooth movement of moving surfaces, and tight fit for non moving surfaces. Depending on the colors you chose and your printer settings, more or less trimming, filing and/or sanding may be required. Carefully file all edges that contacted the build plate to make absolutely sure that all build plate "ooze" is removed and that all edges are smooth. I used a flat jewelers file and plenty of patience to perform this step.Study "Assembly.stl", the cad output of Autodesk Fusion 360 and the photographs carefully noting the locations and positions of the various components as assembly proceeds.Step 2: Assemble and Test

2025-04-18